-

GOODWE®ESTARHOSE®SHANGHAI E-STAR GROUP LTD.

GOODWE®ESTARHOSE®SHANGHAI E-STAR GROUP LTD.

Rubber industrial Hose

PVC Hose

PTFE hose

Hydraulic Fittings

Industrial Fittings

Converyor Belts

- Steel cord conveyor belts

- Chevron Conveyor Belt

- Chemical resistant conveyor belt

- EP/NN/Cotten fabric Belt

- Cross stabilized belt

- Light Duty PVC belt

- Foodstuff conveyor belt

- Endless conveyor belts

- Flat Rubber Belts

- Heat Resistant Conveyor Belts

- Oil Resistant Conveyor Belts

- Flame Resistant Belt

- Cold Resistant Belt

- PVC PVG Solid Woven Belt

- Cross Rigid Conveyor Belt Rip

- Bare Back Conveyor Belting

- Pipe Belting

- Sidewall conveyor belt

- Elevator Conveyor Belting

- Fabric impression belt

- Rough Top Conveyor Belt

Power Transmission Belts

11

-

Product List

Rubber industrial Hose

PVC Hose

PTFE hose

Hydraulic Fittings

Industrial Fittings

Converyor Belts

- Steel cord conveyor belts

- Chevron Conveyor Belt

- Chemical resistant conveyor belt

- EP/NN/Cotten fabric Belt

- Cross stabilized belt

- Light Duty PVC belt

- Foodstuff conveyor belt

- Endless conveyor belts

- Flat Rubber Belts

- Heat Resistant Conveyor Belts

- Oil Resistant Conveyor Belts

- Flame Resistant Belt

- Cold Resistant Belt

- PVC PVG Solid Woven Belt

- Cross Rigid Conveyor Belt Rip

- Bare Back Conveyor Belting

- Pipe Belting

- Sidewall conveyor belt

- Elevator Conveyor Belting

- Fabric impression belt

- Rough Top Conveyor Belt

Power Transmission Belts

11

-

HOME >Steel cord conveyor belts

Chevron Conveyor Belt

Chemical resistant conveyor belt

EP/NN/Cotten fabric Belt

Cross stabilized belt

Light Duty PVC belt

Foodstuff conveyor belt

Endless conveyor belts

Flat Rubber Belts

Heat Resistant Conveyor Belts

Oil Resistant Conveyor Belts

Flame Resistant Belt

Cold Resistant Belt

PVC PVG Solid Woven Belt

Cross Rigid Conveyor Belt Rip

Bare Back Conveyor Belting

Pipe Belting

Sidewall conveyor belt

Elevator Conveyor Belting

Fabric impression belt

Rough Top Conveyor Belt

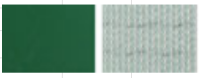

Light Duty PVC belt

I. Description:

Light duty conveyor belt have a wide range, to suit almost all the Industries under roof.

Our light duty industrial conveyor belts are manufactured with various base fabrics like polyester, nylon, cotton, etc., and surface coating with PVC/PU/PE/TPE, etc.

These belts are available in White, Green, Black or any other color according to specific requirement, up to 3000 mm wide.

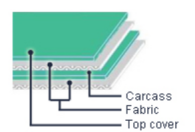

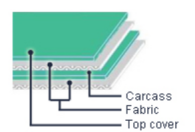

Construction:

II. Code and Abbreviations:

Type of material:

C PVC

U PU (polyurethane)

E PE (polyethylene)

T TPE polyethylene (Hytrel®)

S Silicon

P polyamide

Type of fabric:

0 Polyester spun, strong structure

1 Polyester multifilament

2 Polyester monofilament, with lateral stability, strong structure

3 Polyester / Cotton

4 Polyester spun

5 Polyester monofilament, with lateral stability

6 Cotton

7 Polyester multifilament, heavy construction, with lateral stability

8 Polyester multifilament, heavy construction

W Felt

Code of color:

T natural/transparent

G green

W white

B black

GR grey

R red

BR brown

P petrol

BL blue

O orange

Special characteristics (material):

O Oil resistant

F flame resistant

C Conductive(105Ω )

Special characteristics (fabric):

A Anti-static carbon fiber

D Low noise fabric

I Impregnated fabric

G Extra rigid fabric(Latitudinal thicker)

L Low shrink rate fabric(Longitudinal stronger)

III. Surface Patterns:

S00 S01 smooth S02 matt finishing

S03 rough matt finishing S04 S05

S06 S07 SO8

S09 S10 S11

S12 S13 S14

S15 S16 S17

S18 S19 S20

S21 S22 S23

S24 S25 S26

S27 S28 fine fabric impression S29 rough fabric impression IV. Application:

Logistics and Airports:

We supply a wide range of Light Duty Conveyor Belts suitable for the logistics sector and airports. They are low noise, low elongation,abrasion resistant and easy to install. They are widely used in super market, warehouse, postal package, distribution centre, airport check-in area, security check etc.

The normal types are as follows:

C25-G20-S0105/S00A

Color Total thickness (mm) Weight (kg/m2) Top cover thickness (mm) Top Coating Shore A Working Temp. (°C) Pull for 1% Elongation (N/mm) Min. Pulley Dia.(mm) Max. Width(mm) Lateral Stability G 2 2.3 0.5 80 -0.1875 8 40 3000 * C25-G21-S0506/S00A

Color Total thickness (mm) Weight (kg/m2) Top cover thickness (mm) Top Coating Shore A Working Temp. (°C) Pull for 1% Elongation (N/mm) Min. Pulley Dia.(mm) Max. Width(mm) Lateral Stability G 2.1 2.2 0.6 80 -0.1875 8 40 3000 * C21-G20-S0105/S00CA

Color Total thickness (mm) Weight (kg/m2) Top cover thickness (mm) Top Coating Shore A Working Temp. (°C) Pull for 1% Elongation (N/mm) Min. Pulley Dia.(mm) Max. Width(mm) Lateral Stability G 2 2.3 0.5 70 -0.1875 12 30 3000 C25-G30-S0110/S00A

Color Total thickness (mm) Weight (kg/m2) Top cover thickness (mm) Top Coating Shore A Working Temp. (°C) Pull for 1% Elongation (N/mm) Min. Pulley Dia.(mm) Max. Width(mm) Lateral Stability G 3 3.3 1 80 -0.1875 8 60 3000 * C22-G55-S0435/S00D

Color Total thickness (mm) Weight (kg/m2) Top cover thickness (mm) Top Coating Shore A Working Temp. (°C) Pull for 1% Elongation (N/mm) Min. Pulley Dia.(mm) Max. Width(mm) Lateral Stability G 5.5 4 3.5 55 -0.333333333 10 80 2000 * C22-G31-S0106/S05

Color Total thickness (mm) Weight (kg/m2) Top cover thickness (mm) Top Coating Shore A Working Temp. (°C) Pull for 1% Elongation (N/mm) Min. Pulley Dia.(mm) Max. Width(mm) Lateral Stability G 3.1 3.1 0.6 80 -0.1875 10 60 3000 * C32-G46-S0110/S05

Color Total thickness (mm) Weight (kg/m2) Top cover thickness (mm) Top Coating Shore A Working Temp. (°C) Pull for 1% Elongation (N/mm) Min. Pulley Dia.(mm) Max. Width(mm) Lateral Stability G 4.6 5 1 80 -0.1875 15 100 3000 * C32-G38-S0110/S00A

Color Total thickness (mm) Weight (kg/m2) Top cover thickness (mm) Top Coating Shore A Working Temp. (°C) Pull for 1% Elongation (N/mm) Min. Pulley Dia.(mm) Max. Width(mm) Lateral Stability G 3.8 4.1 1 80 -0.1875 15 120 3000 * C21-B20-S0205/S00

Color Total thickness (mm) Weight (kg/m2) Top cover thickness (mm) Top Coating Shore A Working Temp. (°C) Pull for 1% Elongation (N/mm) Min. Pulley Dia.(mm) Max. Width(mm) Lateral Stability B 2 2.3 0.5 80 -0.1875 12 30 3000 C25-B20-S0205/S00

Color Total thickness (mm) Weight (kg/m2) Top cover thickness (mm) Top Coating Shore A Working Temp. (°C) Pull for 1% Elongation (N/mm) Min. Pulley Dia.(mm) Max. Width(mm) Lateral Stability B 2 2.3 0.5 80 -0.1875 8 40 3000 * C22-B25-S0207/S00D

Color Total thickness (mm) Weight (kg/m2) Top cover thickness (mm) Top Coating Shore A Working Temp. (°C) Pull for 1% Elongation (N/mm) Min. Pulley Dia.(mm) Max. Width(mm) Lateral Stability B 2.5 2.7 0.7 80 -0.125 8 25 3000 * C25-B21-S0506/S00A

Color Total thickness (mm) Weight (kg/m2) Top cover thickness (mm) Top Coating Shore A Working Temp. (°C) Pull for 1% Elongation (N/mm) Min. Pulley Dia.(mm) Max. Width(mm) Lateral Stability B 2.1 2.2 0.6 80 -0.1875 8 40 3000 * C22-B55-S0435/S00D

Color Total thickness (mm) Weight (kg/m2) Top cover thickness (mm) Top Coating Shore A Working Temp. (°C) Pull for 1% Elongation (N/mm) Min. Pulley Dia.(mm) Max. Width(mm) Lateral Stability B 5.5 4 3.5 55 -0.333333333 10 80 2000 *  HOME >Steel cord conveyor belts

HOME >Steel cord conveyor belts

Chevron Conveyor Belt

Chemical resistant conveyor belt

EP/NN/Cotten fabric Belt

Cross stabilized belt

Light Duty PVC belt

Foodstuff conveyor belt

Endless conveyor belts

Flat Rubber Belts

Heat Resistant Conveyor Belts

Oil Resistant Conveyor Belts

Flame Resistant Belt

Cold Resistant Belt

PVC PVG Solid Woven Belt

Cross Rigid Conveyor Belt Rip

Bare Back Conveyor Belting

Pipe Belting

Sidewall conveyor belt

Elevator Conveyor Belting

Fabric impression belt

Rough Top Conveyor Belt

-

contact us

-

SHANGHAI E-STAR GROUP LTD.Add:Room1212, No.16 XinYuan Rd., Shanghai P.R. China

SHANGHAI E-STAR GROUP LTD.Add:Room1212, No.16 XinYuan Rd., Shanghai P.R. China